EPS 032 PRO LAMBDA

EPS graphite panels produced by foaming polystyrene and intended for thermal insulation of walls, including facade insulation.

Product features:

- Code of designation: EPS EN 13163 T(1)-L(2)-W(2)- Sb(5)-P(5)-BS100-DS(N)2-DS(70,-)2-TR100,

- Declared thermal conductivity coefficient λD ≤ 0,032 (W/(mK),

- Standards dimensions tof the panel 1000 x 500 mm. (untypical dimensions on request.),

- Panel thickness: 10 – 500 mm,

- Panels can be produced with straight or milled edges.

APPLICATION OF EPS 032 PRO LAMBDA

EPS 032 PRO LAMBDA polystyrene panels applied in insulations which require shifting of extensive mechanical load, among others.:

- Insulation of walls in external thermal insulation composite systems ETICS (light-wet method),

- insulation of multi-layer walls with ventilated and unventilated air gap,

- insulation of tie beams as formwork lost for plaster,

- insulation of windowsill reinforcements and window reveal,

- insulation in external prefabricated sandwich panels,

- insulation of ceiling from below in external thermal insulation composite systems ETICS,

- Insulation of steep roofs under bearing structure.

Due to the increased heat absorption of EPS 032 PRO LAMBDA polystyrene panels,it is recommended that before fixing:

- sand the panels with special grinders on the glued side,

- protect both the substrate and the polystyrene panels from sunlight.

In order to protect the polystyrene panels from direct sunlight during insulation work, it is recommended to use scaffolding nets.

details

PANELS TECHNICAL SPECIFICATION EPS 032 PRO LAMBDA

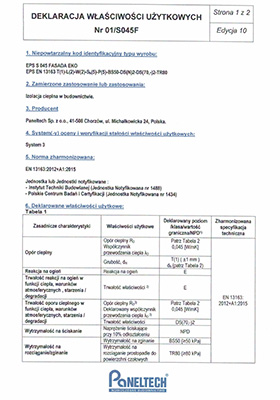

| Properties | Class | Required |

| Thickness | T(1) | ±1 mm |

| Length | L(2) | ±2 mm |

| Width | W(2) | ±2 mm |

| Rectangularity | Sb(5) | ±5 mm |

| Flatness | P(5) | ±5 mm |

| Bending strength | BS100 | ≥100 kPa |

| Dimensional stability under constant normal laboratory conditions | DS(N)2 | ±0,2% |

| Dimensional stability under specific temperature and humidity conditions | DS(70,-)2 | ≥2% |

| Tensile strength perpendicular to faces | TR100 | ≥ 100 kPa |

| Reaction-to-fire class | E | |

| Declared thermal conductivity coefficient λD | ≤0,032(W/(mK) |

TABLE OF THERMAL RESISTANCE EPS 032 Pro Lamba

| Panel thickness (mm) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

| RD(m²K/W) | 0,30 | 0,60 | 0,90 | 1,25 | 1,55 | 1,85 | 2,15 | 2,50 | 2,80 | 3,10 |

| Panel thickness (mm) | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 |

| RD(m²K/W) | 3,40 | 3,75 | 4,05 | 4,35 | 4,65 | 5,00 | 5,30 | 5,60 | 5,90 | 6,25 |

| Panel thickness (mm) | 210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 | 290 | 300 |

| RD(m²K/W) | 6,55 | 6,85 | 7,15 | 7,50 | 7,80 | 8,10 | 8,40 | 8,75 | 9,05 | 9,35 |