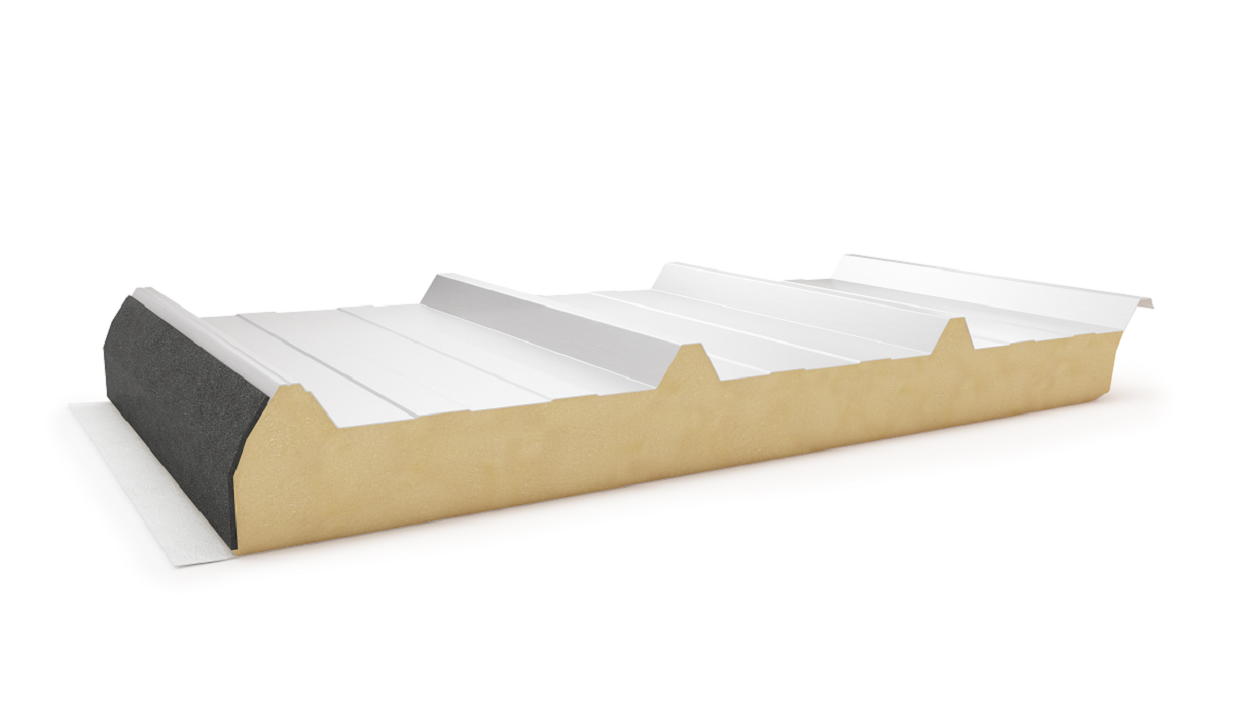

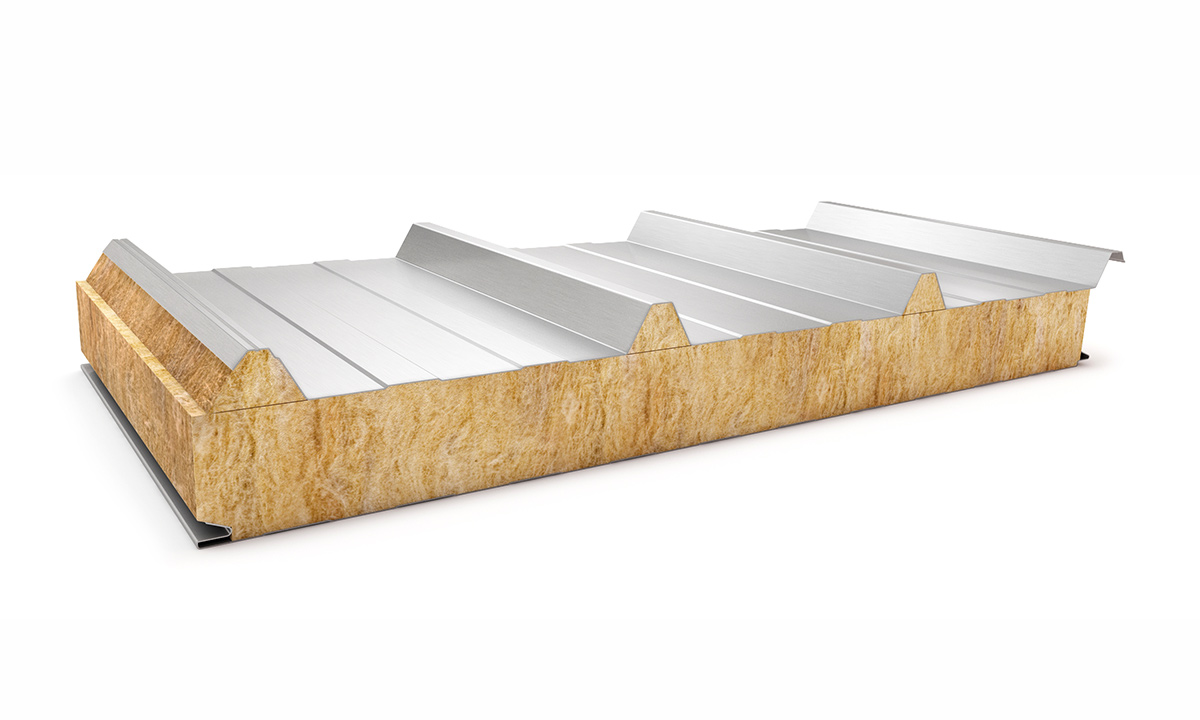

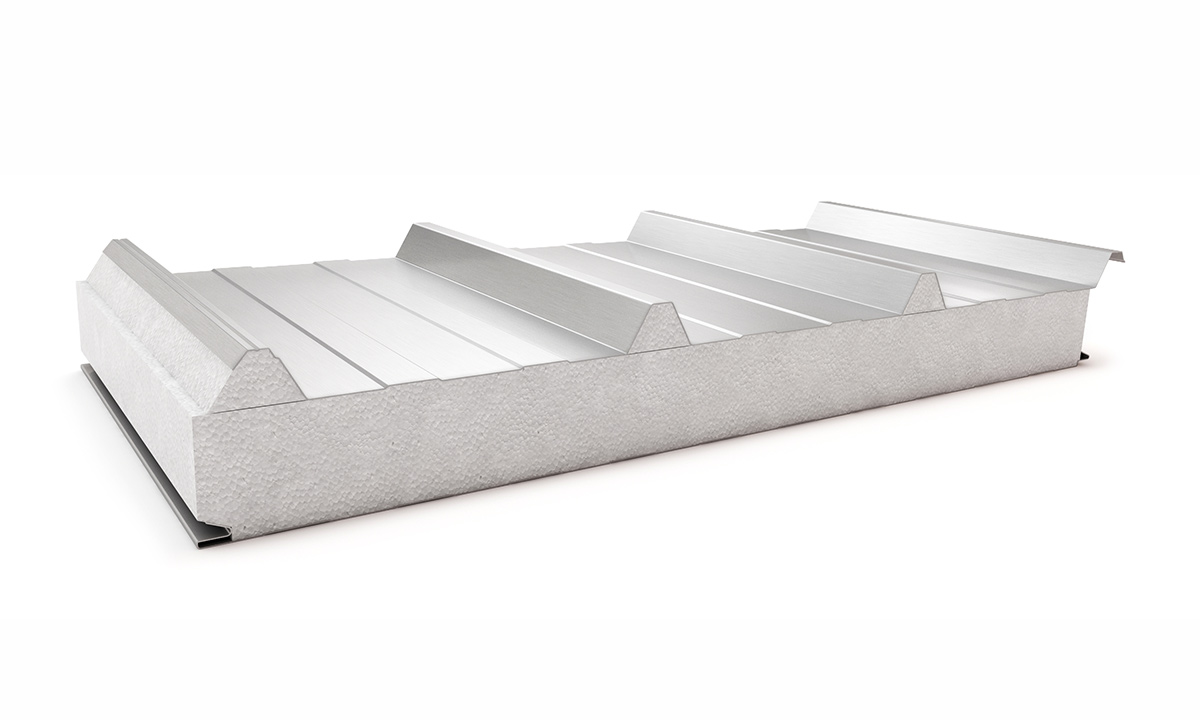

Sandwich panels PWPUR-D/ PWPIR-D AGRO

PWPUR-D / PWPIR-D AGRO Paneltech roof sandwich panel is intended for roofing and roofing in warehouse and production facilities, especially agricultural ones.

The thermal insulation core of the panel consists of rigid polyurethane (PUR) or polyisocyanurate (PIR) foam with a density of 40 kg/m³.

The roof sandwich panel with a fiberglass facing and a PIR or PUR core ensures long-term, trouble-free use of livestock buildings in temperatures ranging from -40°C to +60°C. It also provides a high level of anti-corrosion protection, which is unmatched by panels with organic-coated steel facings..

application of PWPIR-D / PWPUR-D AGRO

In particular PWPIR-D / PWPUR-D AGRO panels can be applied in:

- warehouses,

- sheepfold,

- chickencoop,

- pigsty,

- cowshed.

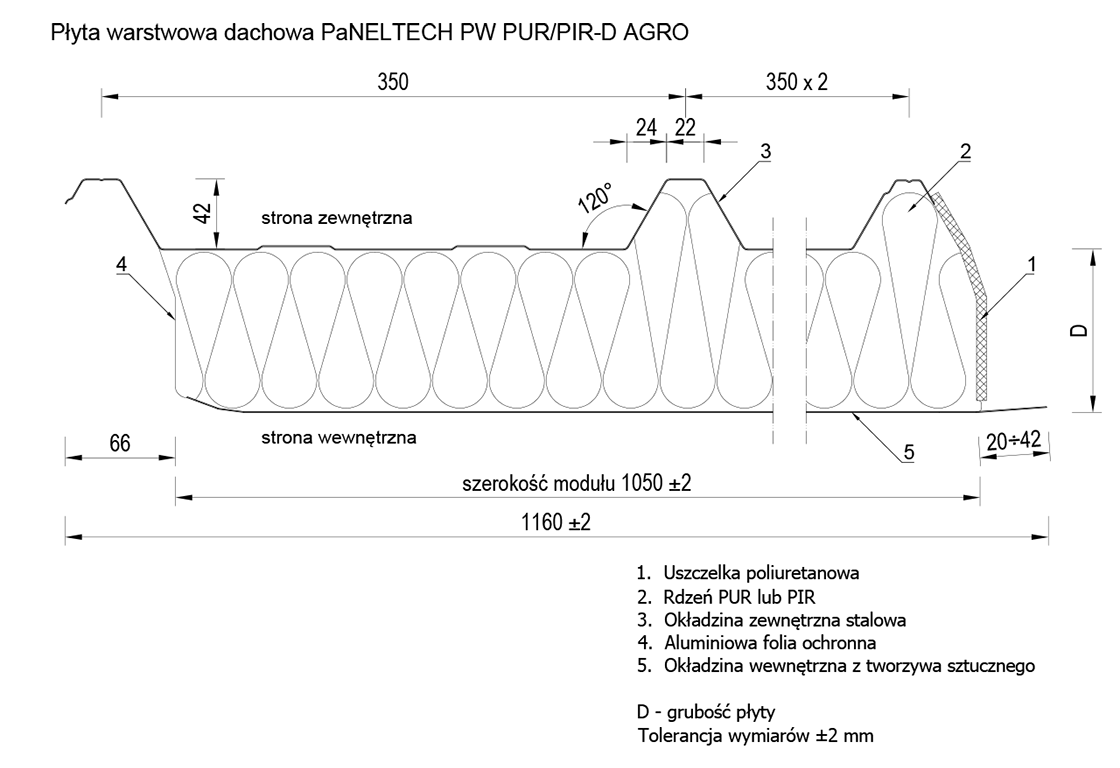

details

- Parameters

- technical drawings

- available profilation types

- available colors

- available protective coatings

- download

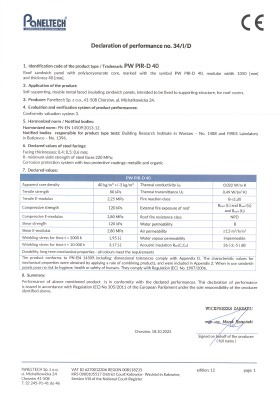

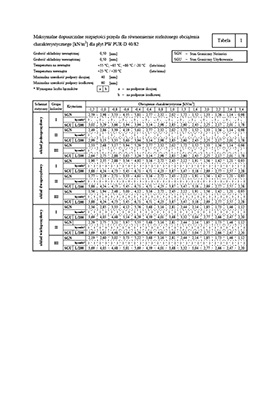

TABLE OF TECHNICAL PARAMETERS OF THE PWPIR-D / PWPUR-D AGRO

| thickness [mm] | 40 | 60 | 80 | 100 | 120 | 160 | |

| modular width [mm] | 1050 | ||||||

| lenght1) [mm] | 2000 ÷ 12000 | ||||||

| weight2) [kg/m2] | 6,75 | 7,55 | 8,35 | 9,15 | 9,95 | 11,25 | |

| thermal resistance R [m2K/W] | 2,10 | 2,95 | 3,85 | 4,70 | 5,55 | 7,30 | |

| Heat transfer coefficient Uc for PW PIR-D [W/m2K] | 0,50 | 0,35 | 0,27 | 0,22 | 0,18 | 0,14 | |

| Thermal conductivity [W/mK] | 0,023 | ||||||

| roof resistance to external fire PIR | Broof(t1) | ||||||

| external facing | galvanized sheet 0,5 mm | ||||||

| organic coatings | SP 25, PU, FARM and others 3) | ||||||

| anti-corrosive protection | C1, C2, C3 (C4÷C5)3) | ||||||

| internal facing | fiberglass with a thickness of min. 0.47mm | ||||||

| corrosion resistance of the internal facing | resistant to aggressive environmental factors | ||||||

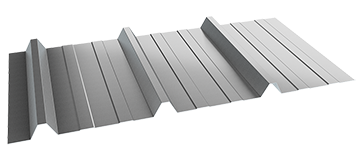

| available profiles | external facing T; ; internal facing G | ||||||

| insulating core | rigid foam of 40 kg/m3 in total density and with enclosed PUR (polyurethane) / PIR (polyisocyanurate) cells | ||||||

| application | non-continuous application on roofs and roof covers | ||||||

1) length depends on the color of the external facing and the thickness of the panel

2) average weight of a sandwich panel with 0.5 mm outer facing, including product tolerance

3) organic coat selected on the basis of durability and application conditions. Coat selection is carried out through environmental assessment and basing on an environmental questionnaire completed by the Client, approved by the steel manufacturer and Paneltech

AVAILABLE EXTERNAL PROFILATION:

AVAILABLE INTERNAL PROFILATION:

Standards colors

Typical colors

Untypical colors

TABLE OF COATING PROPERTIES

| NAME | TYPE | THICKNESS [μm] | CORROSION RESISTANCE |

APPLICATION | SSURFACE FINISHING2) |

| SP25 | polyester | 25 | C1-C3, A1 | common | smooth |

| PU | polyurethane | 35-60 | conditionally C51), A41) | environment with increased corrosion class | smooth with shine |

| FARM | polyester | 35 | conditionally C3, A1 | from inside of buildings (no UV-resistance), agricultural buildings, high resistance to ammonia | smooth |

| specjalna | polyvinyl chloride | 200 | conditionally C51), A51) | environment with high corrosion resistance class | scintilla finishing |

| PVDF / polyurethane | 40-65 | conditionally C51), A51) | environment with high corrosion resistance class, high colour fastness | smooth |

1) 1) organic coating is selected on the basis of its durability and application conditions. Coating selection is carried out through environmental assessment based on an environmental questionnaire completed by the Client, approved by the steel manufacturer and Paneltech

2) a term not described by a standard.