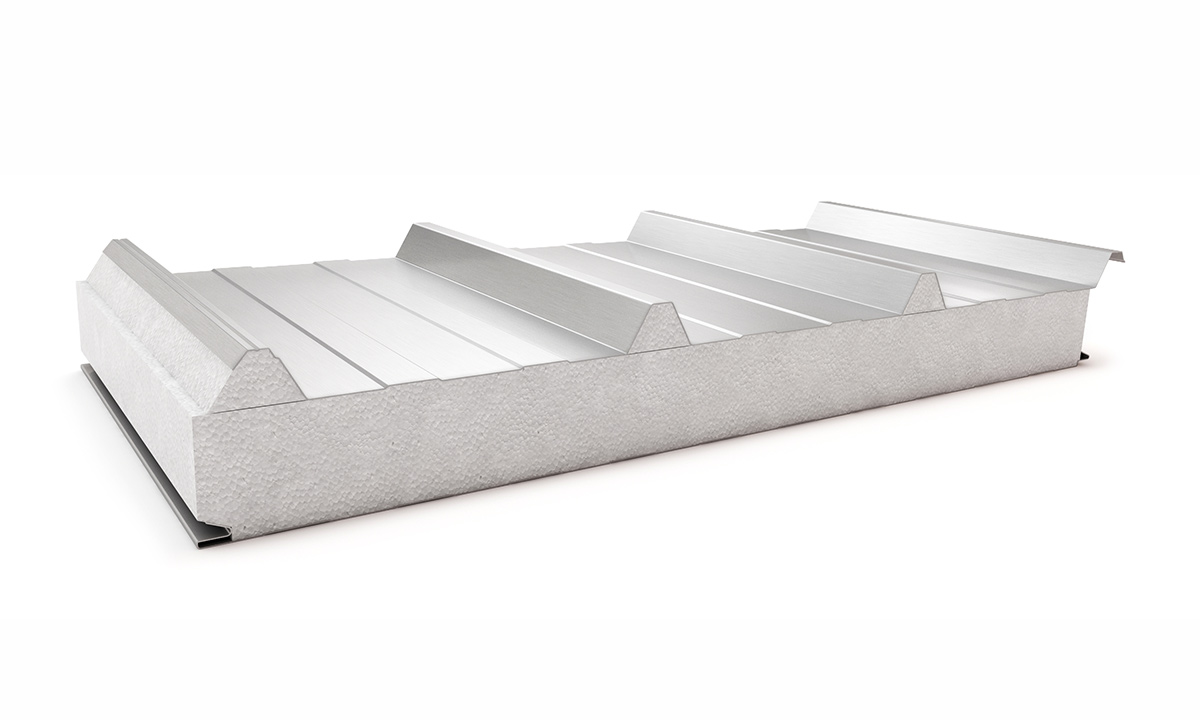

ROOF PANEL PWS-D

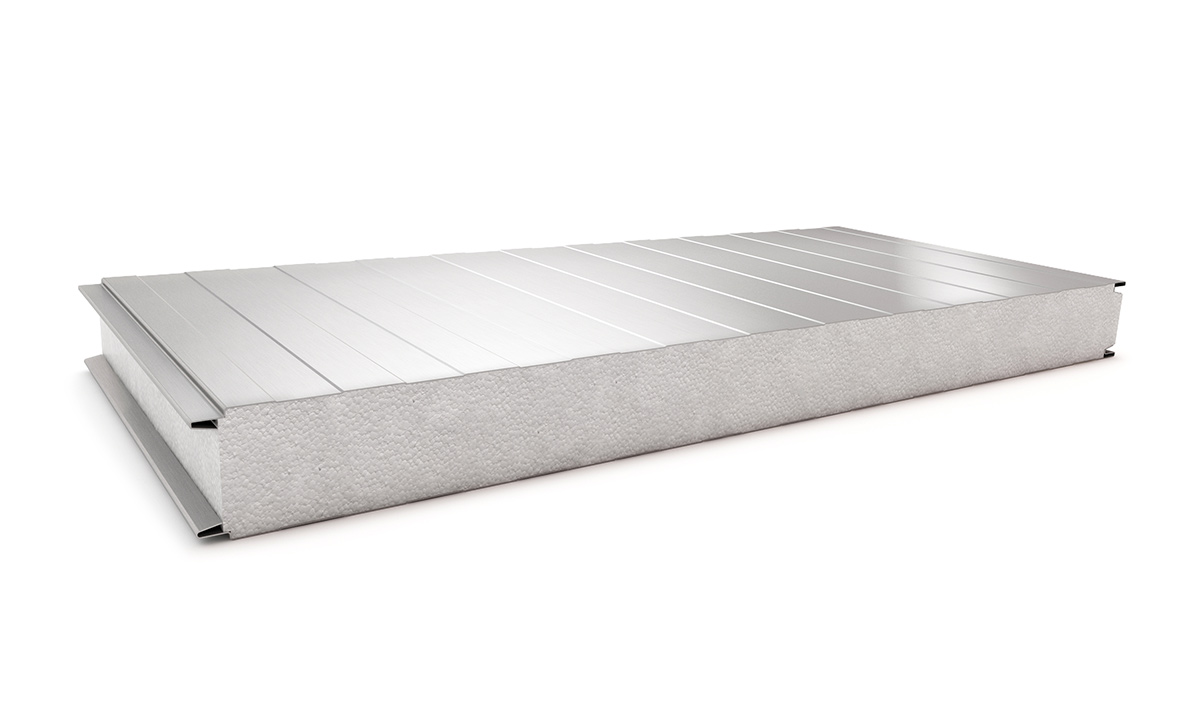

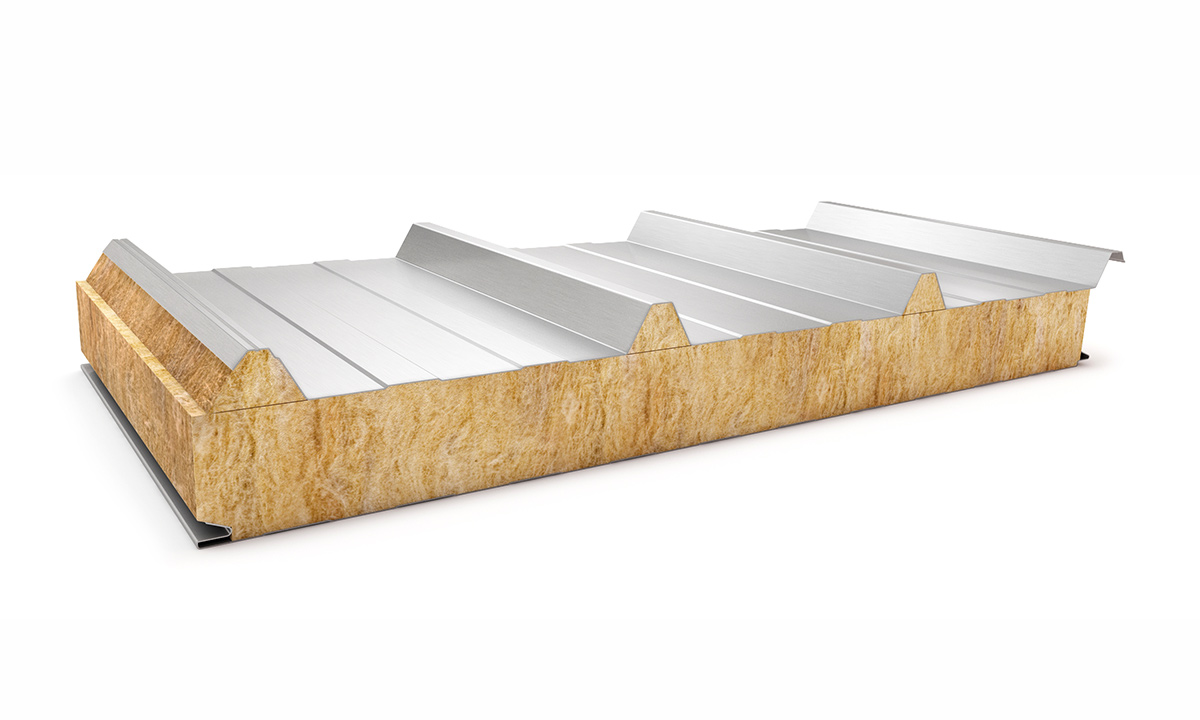

PWS-D roof sandwich panel with a polystyrene core is designed for roofing and roof coverings on skeletal structures, particularly in buildings where low investment cost is a key criterion.

This panel is characterized by good thermal insulation performance, lightweight construction, and an attractive price. It is fully compatible with PWW-D roofing panels and externally compatible with PWW-D roofing panels with a mineral wool core, as well as PWPIR-D, PWPIR-D LITE, and PWPUR-D roofing panels.

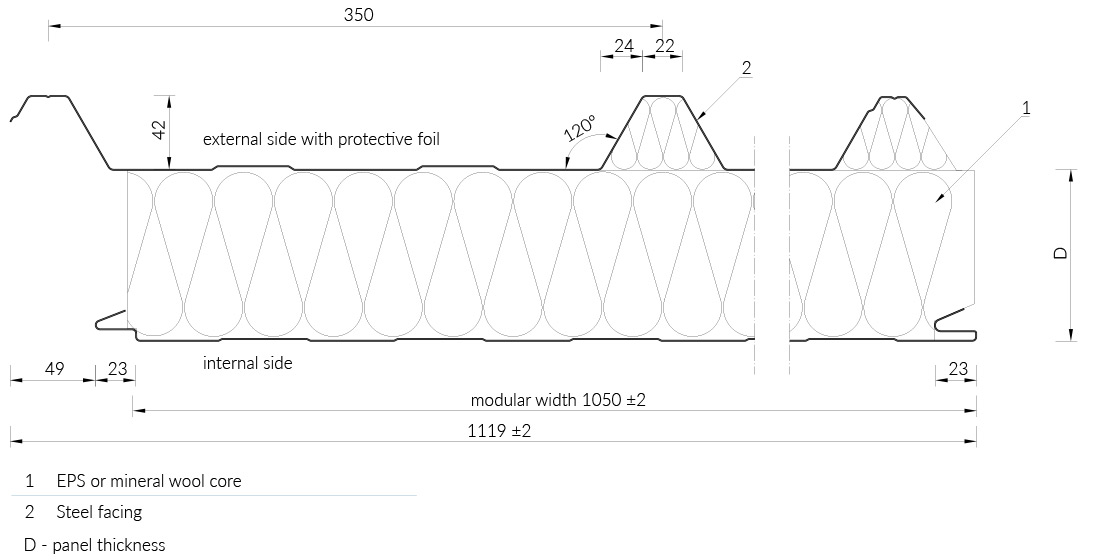

The thermal insulation core of the panel consists of in-house produced polystyrene with a density of 12.5 kg/m³. The external layers are made of galvanized steel sheets coated with organic protective layers, available in various colors and with different properties. The outer side features a distinctive high trapezoidal profiling, ensuring durability and structural integrity.

APPLICATION OF PWS-D PANELS

- Industrial buildings,

- Store houses and logistic centres,

- Coldrooms and freezers,

- Commercial buildings and offices,

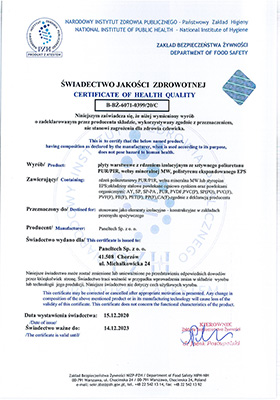

- Food industry facilities,

- Agricultural objects

- Sport halls.

MORE ABOUT PANELS

- PARAMETERS

- technical drawings

- AVAILABLE PROFILATION TYPES

- AVAILABLE COLORS

- AVAILABLE PROTECTIVE COATINGS

- DOWNLOAD

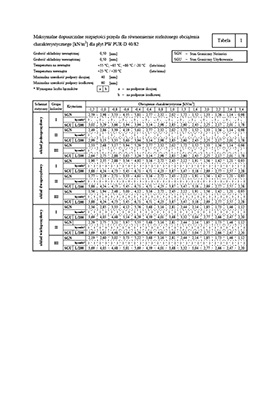

TABLE OF TECHNICAL PARAMETERS OF THE PWS-D PANELS1)

| thickness [mm] | 80 | 100 | 120 | 150 | 200 |

| modular width [mm] | 1050 | ||||

| length2) [mm] | 2000 ÷ 10000 | ||||

| weight3) [kg/m2K] | 9,6 | 9,9 | 10,2 | 10,6 | 11,5 |

| heat transfer coefficient Uc [W/m2K] | 0,45 | 0,37 | 0,31 | 0,25 | 0,19 |

| roof resistance to external fire | Broof(t1) | ||||

| anti-corrosive protection | depending on the coating used4) | ||||

| organic coatings | SP 25,PU,AGRO, FOOD SAFE and other4) | ||||

| external facing | galvanized sheet 0,5 ÷ 0,6 mm5) | ||||

| internal facing | galvanized sheet 0,4 ÷ 0,5 mm5) | ||||

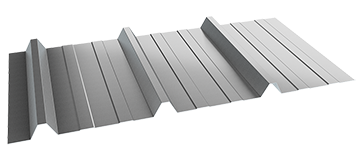

| available profiles | external facing T; internal facing L, R6, G6) | ||||

| insulating core | expanded polystyrene EPS of 12,5 kg/m3 | ||||

| application | non-continuous application on roofs and roof covers | ||||

2) length depends on the color of the external facing and the thickness of the panel

3) average weight of a sandwich panel with 0,5 mm outer facing, including product tolerance

4) organic coat selected on the basis of durability and application conditions. Coat selection is carried out through environmental assessment and basing on an environmental questionnaire completed by the Client, approved by the steel manufacturer and Paneltech

5) other steel types are selected according to application conditions and approved by Paneltech

6) panels with G – smooth or R – groove facing may include micro-waving, which can affect the aesthetic appeal of the product which is classified as fully compliant with EN 14509, annex D

The profiling of sandwich panel is intended to emphasize aesthetic values as well as increase stiffness. Depending on the type of panel, various variants of profiling are available on both sides. The depth of profiling is approximately 1 mm. The exception is the external facing of the roof panels, which has an individual trapezoidal T profile, approximately 2 mm deep.

AVAILABLE EXTERNAL PROFILATION:

AVAILABLE INTERNAL PROFILATION:

standard colors

typical colors2)

untypical colors

1)Internal sandwich panel facings are available in two basic colors: RAL 9002 and 9010. Other colors available on request.

2)Availability of these colors depends on current stock and has to be confirmed by sales before order. Untypical colors – for individual request.

The colors presented on this webside are for reference only. Steel sheet tones may differ, depending on the material batch and the manufacturer. Paneltech Sp. z o.o. therefore admits the possibility of occurrence of color differences between the samples presented and the colors of materials supplied.

TABLE OF COATING PROPERTIES

| NAME | TYPE | THICKNESS [μm] | CORROSION RESISTANCE |

APPLICATION | SURFACE FINISHING2) |

| SP25 | polyester | 25 | C3/C1, A1 3) | common | smooth |

| PU | polyurethane | 35-60 | conditionally C51), A41) | environment with increased corrosion class | smooth with shine |

| FARM | polyester | 35 | conditionally C3, A1 | from inside of buildings (no UV-resistance), agricultural buildings, high resistance to ammonia | smooth |

| FOOD SAFE | PVC laminate | 120 | conditionally C51), A51) | from inside of buildings (no UV-resistance), premises with controlled environmental parameters: cold stores, clean rooms, e.g. meat processing plants |

matt / grainy |

| special | polyvinyl chloride | 200 | conditionally C51), A51) | environment with high corrosion resistance class | scintilla finishing |

| PVDF / polyurethane | 40-65 | conditionally C51), A51) | environment with high corrosion resistance class, high colour fastness | smooth |

1) organic coating is selected on the basis of its durability and application conditions. Coating selection is carried out through environmental assessment based on an environmental questionnaire completed by the Client, approved by the steel manufacturer and Paneltech

2) applies to the standard warranty. It is possible to extend the warranty according to reference 1).

3) C3 applies to the standard external cladding warranty: C1, A1 applies to standard warranty for internal cladding. The warranty may be extended in accordance with reference 1).